Since the beginning of the 21st century, digitization has experienced exponential growth, driven by trends such as the Internet of Things (IoT), Smart Cities and Industry 4.0. This advancement has generated a massive amount of data from sensors, connected devices and industrial systems. In this context, Artificial Intelligence (AI) and Big Data have emerged as essential tools to process, analyze and extract value from this information, facilitating data-driven decision making.

Data visualization tools play a key role in this process by transforming complex information into intuitive and easy-to-interpret graphical representations. These tools allow users to create diagrams, interactive dashboards, heat maps and other visual representations that reveal patterns and trends in large volumes of data. Their main purpose is to identify critical analyses, detect anomalies, compare information and facilitate human-machine interaction.

Data visualisation in Industry 4.0 has become a key element in improving operational efficiency. It allows for centralised monitoring, provides real-time information, and optimises resource management. Companies that adopt visual analytics tools can improve their understanding of their processes, anticipate failures, and make strategic decisions based on accurate data.

Augmented Reality: more efficient data visualisation

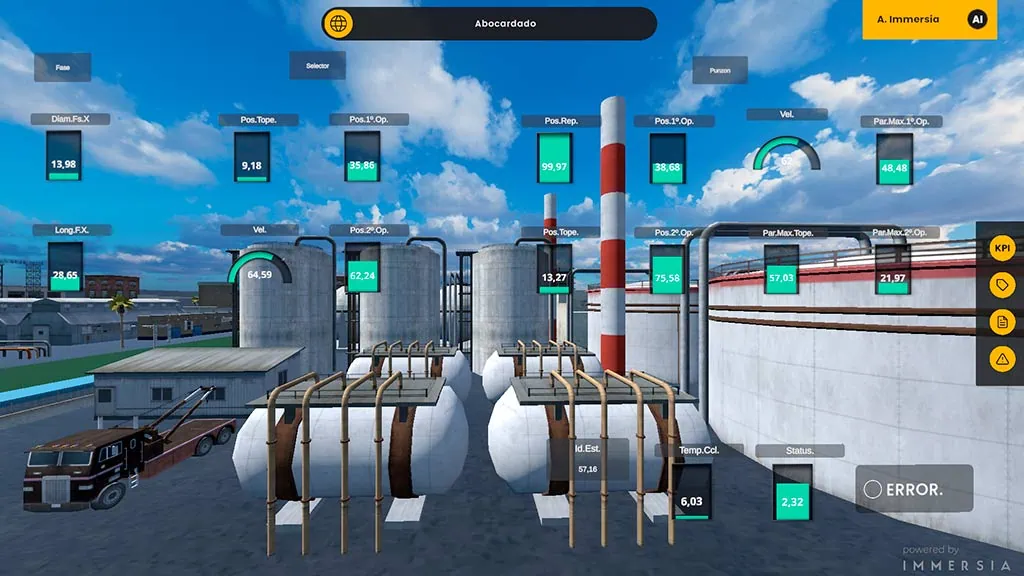

In this context, Augmented Reality represents a qualitative leap in data visualisation, as it allows for much more intuitive and efficient interaction with information. Unlike traditional visualisations on 2D screens, AR integrates data into the user’s physical environment, projecting graphics, indicators and models in three dimensions onto real space. This facilitates understanding at a cognitive level, as the representation of data in immersive environments helps to perceive relationships and patterns more clearly and naturally.

The use of augmented reality in industrial environments is transforming the way operators and plant managers access information. For example, when monitoring machinery, technicians can view operational data superimposed in real time on the equipment, without the need to consult physical panels or external screens. This allows them to detect faults, receive alerts and access interactive manuals at a glance, improving efficiency and reducing downtime.

Another application of AR in data visualisation is warehouse and logistics management. Operators can use augmented reality glasses or devices to view information about product locations, optimal picking routes, and inventory levels without interrupting their work. This optimises warehouse management and reduces human error in order preparation.

This technology also plays a key role in industrial maintenance. Thanks to it, technicians can view detailed information about machine components, receive step-by-step instructions on repair tasks, or even perform remote diagnostics with the help of remotely connected experts. This not only streamlines corrective and preventive maintenance, but also contributes to worker safety.

In short, Augmented Reality is revolutionising the way industries visualise and manage their data. By integrating digital information with the real world, this technology not only improves data comprehension, but also optimises decision-making, increases operational efficiency and contributes to a safer and more productive working environment. The combination of visual analytics and AR marks a turning point in Industry 4.0, enabling companies to be more competitive and better prepared for the challenges of the present and the future.