Safety in the industrial environment is a key issue for Nissan Cantabria, and Virtual Reality technology has become a great ally in this process. In order to reinforce awareness of occupational hazards in the plant, we have developed an immersive application that allows workers to virtually walk through the foundry and machining areas, identifying up to 70 potential risks in an interactive and realistic way.

As Nuria Hernández, Manufacturing Section Manager of Nissan’s Machining Workshop 1, comments, having carried out this exercise using Virtual Reality technology has been a very innovative experience: “I have felt a very immersive sensation, to the point that it seems as if you are in the plant itself. In this way, the concepts of prevention stick better in your head than in traditional risk prevention training”.

An interactive environment for risk identification

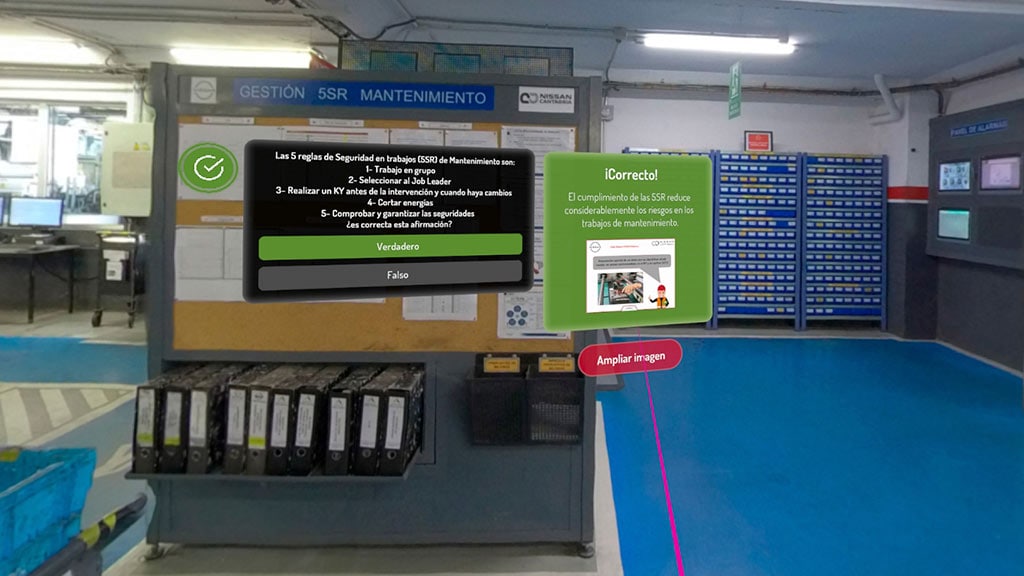

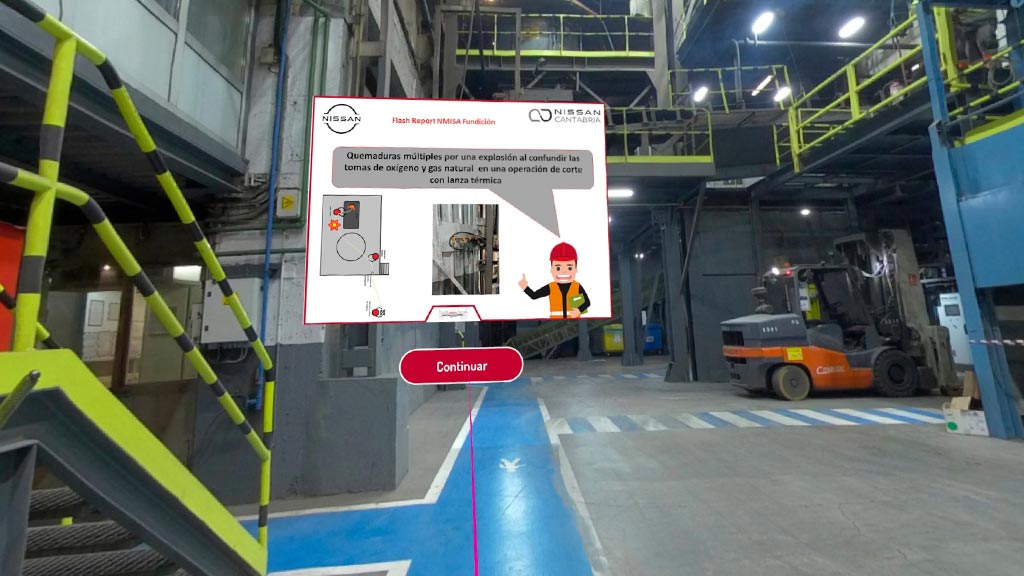

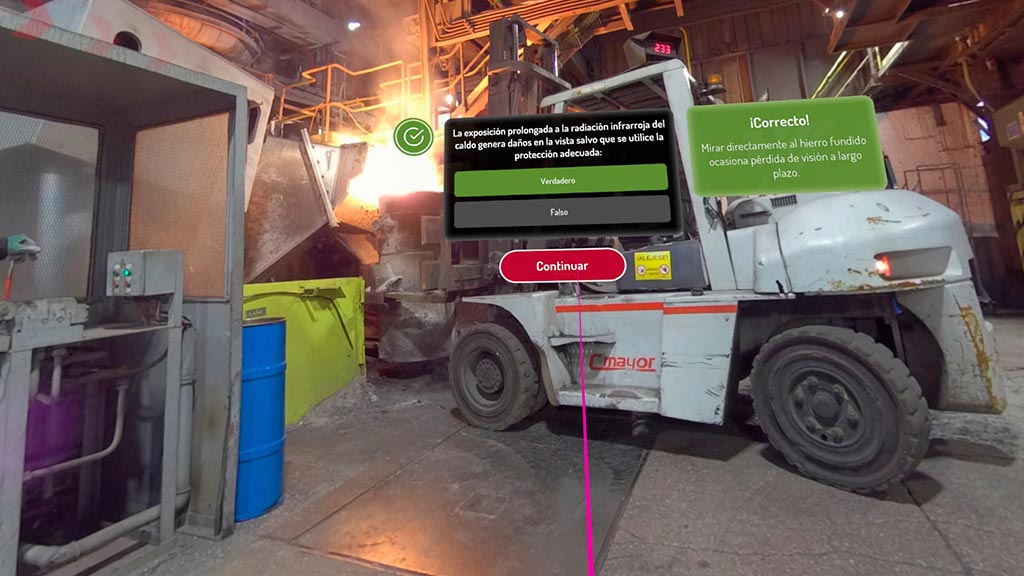

The application allows workers to explore the plant in a navigable digital environment and detect risk situations through different interactive dynamics. In addition, during the experience, users receive information on the hazards identified and how to react to them through explanatory texts, images and videos.

This methodology facilitates the assimilation of occupational risk prevention concepts and reinforces workers’ memory thanks to total immersion in the production environment.

Marcos Sánchez Díaz, head of the H&S department at NMISA and pilot of the project together with Itziar Rodríguez and Pilar Mateu, prevention technicians at the Cantabria plant, is clear that “the implementation of this project to improve risk perception through the use of Virtual Reality glasses is proving to be an innovative and very effective type of training“, as it allows workers to learn to detect the occupational risks present in the production environment and the preventive measures to apply in each case in an interactive way.

Recording and evaluation of the activity

Another key aspect of this application is its ability to record user activity, allowing prevention managers to evaluate performance and identify areas for improvement in training.

This data-driven approach helps to optimise security strategies and tailor future training to the real needs of the workforce.

A before and an after in raising awareness of occupational hazards

The development of this tool has marked a turning point in the way Nissan Cantabria approaches occupational safety training. The combination of immersive technology and interactive learning has led to increased awareness and a lasting impact on risk perception within the plant.

Marcos Sánchez Díaz

Head of the H&S department at NMISA:

“The reality has exceeded expectations. The feedback received from the people who have taken the training has been very positive and, to date, we can say that with this project we have achieved the objective we set ourselves: to increase awareness among the workforce in terms of occupational risk prevention”.

With initiatives like this, Nissan Cantabria reinforces its commitment to safety and innovation, demonstrating that technology can be a key ally in the prevention of occupational hazards and the training of its team.