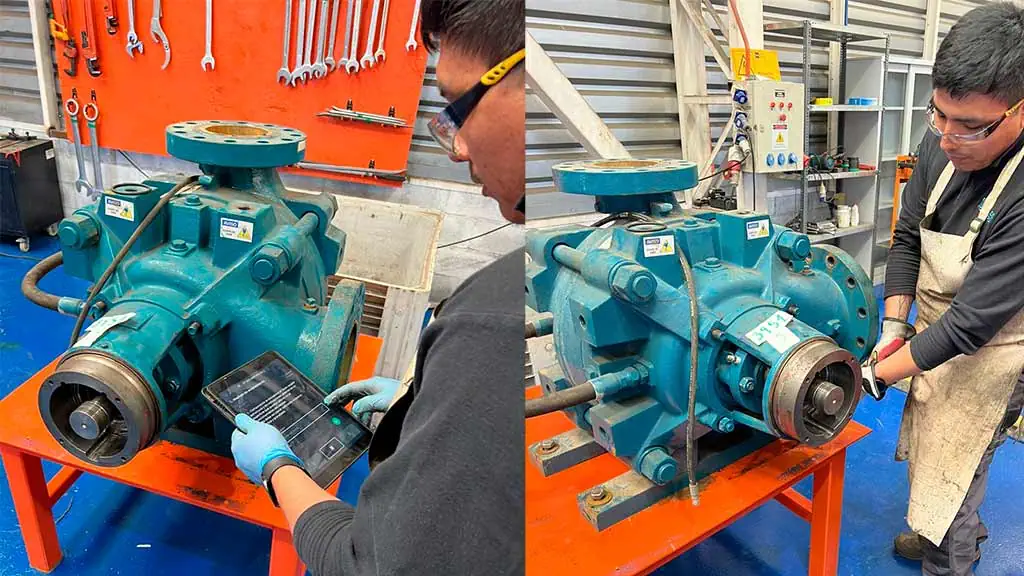

In an increasingly competitive industrial environment, operational efficiency and execution accuracy have become determining factors for success. RepairCo, a company specialized in the remanufacturing of multi-brand centrifugal pumps, has taken a decisive step towards digital transformation by adopting SAAM, our solution for the digitalization of industrial operations.

A challenge shared by the industry

With over a decade of experience in the sector, RepairCo has established itself as a benchmark in predictive and corrective maintenance services for industrial equipment. Its main objective is to ensure the operational continuity of its clients through comprehensive processes that extend the lifespan of their equipment. However, today’s industrial context presents challenges that go beyond technical expertise and demand faster and more accurate information management.

In the field of maintenance, especially in sectors such as mining, pump repair processes are complex and traditionally dependent on paper-based documentation. Manual data management caused delays, errors, and a lack of traceability, making real-time decision-making difficult. Before digitalizing its operations, RepairCo faced slow, error-prone manual recording, poor traceability in repair histories, delayed and dispersed reports, and clear difficulties in standardizing and digitalizing its industrial processes.

RepairCo understood that, in order to maintain its leadership and continue offering excellent service, it needed to embrace digitalization as a key strategic pillar for growth.

SAAM: the platform that revolutionizes technical operations

To overcome these challenges, RepairCo relied on SAAM, our comprehensive platform designed to digitalize and optimize technical operations. SAAM enables companies to record, manage, and analyze all maintenance information within a single digital environment, eliminating paper dependency and improving efficiency at all levels.

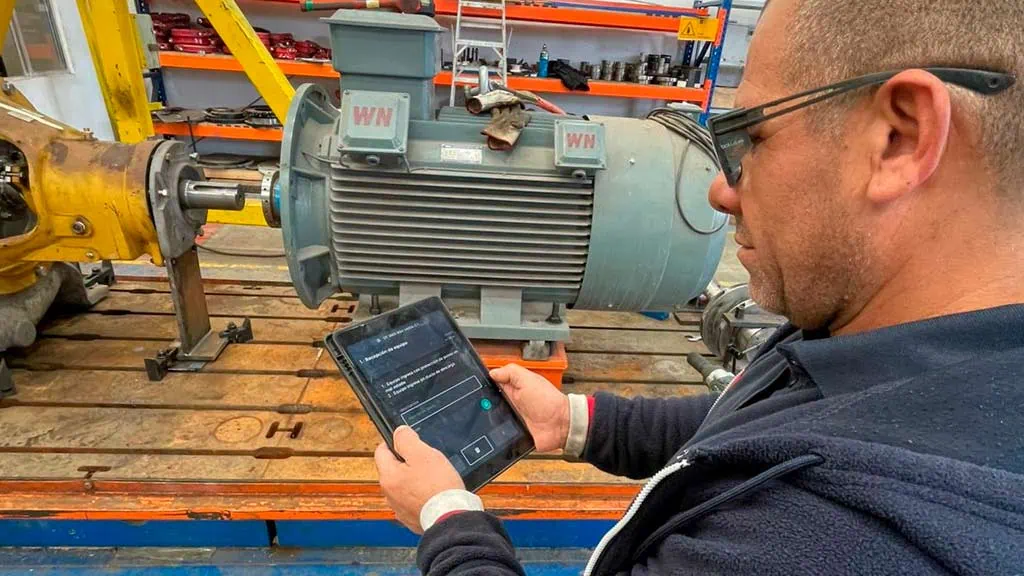

With SAAM’s implementation, RepairCo technicians began recording data in real time directly from their mobile devices, speeding up data collection and drastically reducing human error. All information is automatically synchronized in the cloud, remaining accessible to the entire team and ensuring complete traceability throughout the process.

Another key aspect of this transformation was the automation of reporting. What once took hours or even days of manual work can now be generated in just minutes. SAAM produces standardized, detailed, and visual reports with a single click, completely changing the way RepairCo manages information and communicates results to clients.

Tangible results: greater efficiency, accuracy, and responsiveness

The implementation of SAAM has represented a qualitative leap for RepairCo in terms of productivity and knowledge management. Thanks to digitalization, the company now operates more intelligently, quickly, and reliably, with measurable impacts across all areas of its business. The availability of real-time data allows for immediate detection of issues and faster response times.

The predictive analysis provided by SAAM has improved maintenance planning and the ability to anticipate operational needs. Resource optimization has led to more efficient allocation of personnel and materials, reducing downtime. Additionally, fewer unplanned stoppages and longer equipment life have significantly lowered operational costs.

The results of this transformation are remarkable. RepairCo has achieved a 90% increase in decision-making efficiency, thanks to access to precise and up-to-date information. Report preparation time has been reduced by 87%, as reports are now generated automatically in minutes. Moreover, data accuracy has reached 98.7%, virtually eliminating manual errors.

These figures confirm that technology can be a strategic ally for any company seeking to improve competitiveness and operational sustainability.

Beyond efficiency: building a new digital culture

The impact of SAAM goes far beyond immediate efficiency. RepairCo’s digital transformation has sparked a cultural shift within the organization. Technical teams have adopted a new way of working—based on collaboration, traceability, and transparency. Digitalization has also improved internal communication and enabled the company to offer clients a more agile, documented, and reliable service.

This evolution represents a new stage in the relationship between technology and industrial maintenance. Thanks to SAAM, RepairCo ensures operational continuity, optimizes resources, and delivers added value in every service, reinforcing its commitment to innovation and excellence.

The success story of RepairCo demonstrates that investing in solutions like SAAM is not an expense, but a strategic decision that generates significant returns in efficiency, accuracy, and responsiveness. In an industrial environment moving toward automation and intelligent operations, digitalizing processes is no longer optional—it is essential to remain competitive.

RepairCo has successfully anticipated the future, transforming its operations into a model of technological innovation applied to industrial maintenance. With SAAM, it has not only optimized its processes but also laid the foundations for more agile, connected, and sustainable management.