Safety is an essential value in any industrial environment, but in facilities where flammable materials are handled, it becomes an even greater priority. In this context, Molins, as part of its Circular Economy business, has taken another step forward in its commitment to innovation and prevention with the development of a Virtual Reality training simulator for its plant in Montornès del Vallès (Barcelona).

From waste to the most sustainable fuel

Molins recovers non-hazardous waste and transforms it into recovered solid fuel (RSF) at its Pronatur facilities, 35 km from the cement factory in Sant Vincenç dels Horts (Barcelona). This alternative fuel is mainly used in the cement factory as a substitute for fossil fuels, thus helping to reduce waste, save fossil fuels and move towards a more sustainable construction industry.

However, this activity involves the handling of flammable materials, which requires rigorous and ongoing training in fire protection.

As Miguel Martínez, Circular Economy operator at Molins, explains, “we work with flammable materials and staff must be properly trained because, in the event of a fire, we have to act in a matter of seconds”.

Training without risks or interruptions

Until now, staff had to carry out real drills, which meant stopping production, interrupting processes and generating additional costs. The project was born precisely from this need to offer practical, effective, safe and simple training. To optimise this process, Molins decided to digitise training using a Virtual Reality simulator that replicates the industrial plant and allows real situations to be trained without risk.

According to Edgar Sanabria, Circular Economy production engineer at Molins, “the main challenge we faced was training new recruits, creating a safe environment where this training did not jeopardise plant safety, and implementing all possible technologies to improve the quality of training.” Laura Puigdellosses, Circular Economy Operations Manager at Molins, adds that the goal was “to create a useful and simple application that everyone at the plant would know how to operate.”

An immersive simulator to reinforce prevention

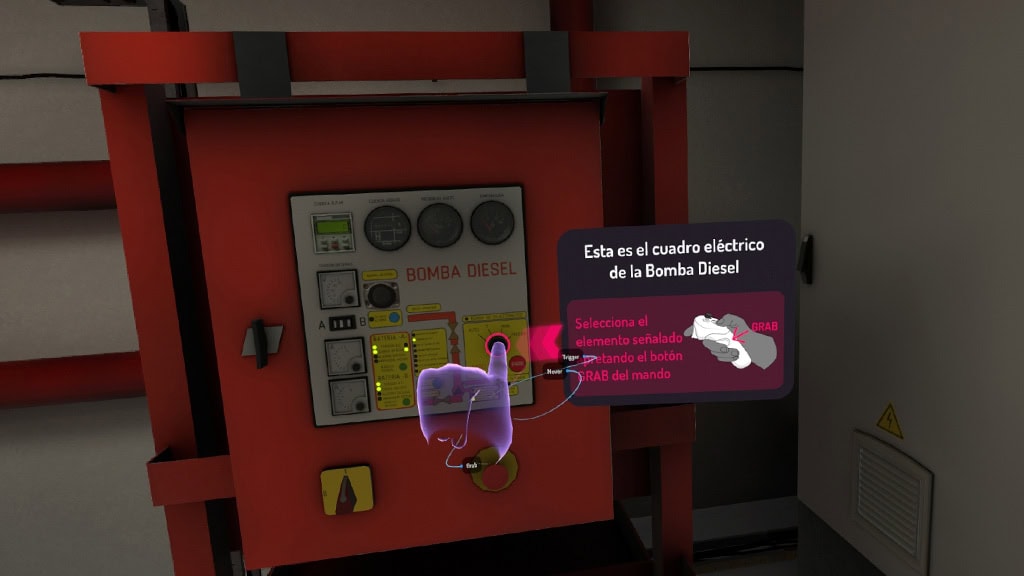

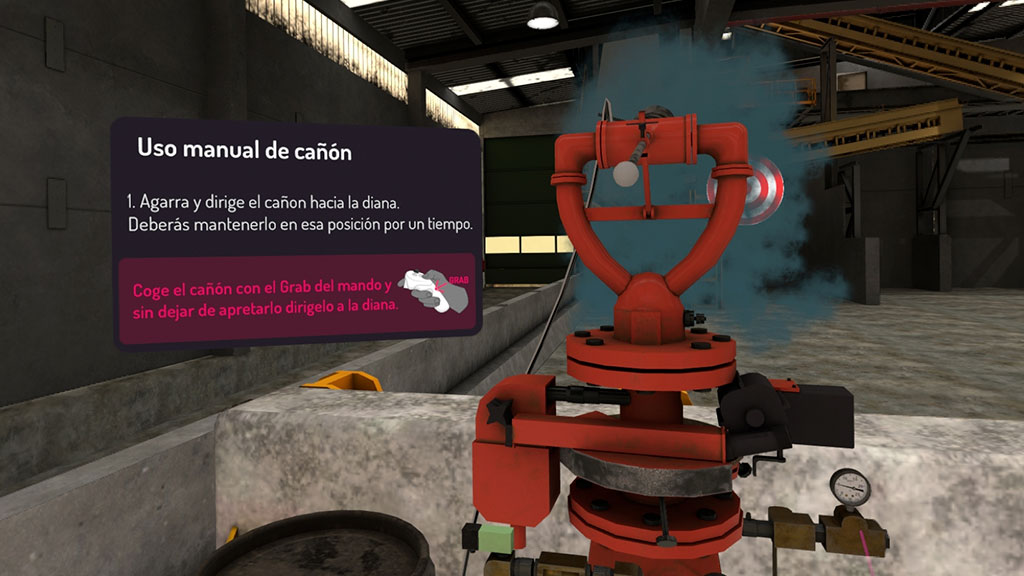

The simulator faithfully reproduces the actual spaces, equipment and procedures of the plant. Using virtual reality glasses or a laptop, operators can learn to identify a fire outbreak, respond correctly to it and normalise the plant once the situation is under control.

The tool also includes a training mode on the correct use of the fire protection equipment available at the plant, and an evaluation mode, with interactive drills and final evaluations. In this way, workers can train their reaction skills in a completely safe and controlled environment.

Adrián Rus, shift manager for Circular Economy at Molins, points out that “we began implementing the measure in May. First, shift managers were trained, and once we are more confident and familiar with the application, we will begin to train the rest of the team.”

For his part, Ángel Simón, Circular Economy operator at Molins, highly values the initiative: “It’s a very good initiative because it allows you to train in a safe environment, you don’t put your physical integrity at risk and you get a more global view.”

Digitalisation and preventive culture

The new simulator is a key tool that promotes safety, efficiency and technological innovation in the industrial field, in line with Molins’ commitment to sustainability, continuous improvement and the digitalisation of its training processes.

This initiative reduces production downtime, increases the frequency of training and improves response to real emergencies, reinforcing the company’s preventive culture.