Industry 4.0

Augmented Reality and Virtual Reality for Industry 4.0

Industry 4.0 has grown rapidly in recent years and is now one of the key sectors driving adoption of AR and VR technologies.

Industry 4.0 has grown rapidly in recent years and is now one of the key sectors driving adoption of AR and VR technologies. At Innovae, we leverage these technologies to upskill the workforce and help operators work more efficiently in increasingly complex production environments.

Ultimately, VR and AR give operators easy, visual access to critical knowledge, enabling them to complete tasks with greater accuracy and efficiency.

Augmented Reality fin Industry 4.0

AR has many applications in Industry 4.0, all aimed at supporting technicians directly in their work environment.

With Augmented Reality, users can follow step-by-step guided processes or receive real-time visual instructions from experts, through teleassistance systems.

Today, AR is widely used in maintenance, assembly processes, and quality control. Leading companies across industries are implementing AR-based solutions to transform and optimize their industrial operations.

Virtual Reality in Industry 4.0

The application of Virtual Reality in Industry 4.0 takes a unique approach due to the high level of immersion it provides to the user.

With Virtual Reality, we create accurate simulations of products, processes, or production plants, allowing users to experience their operation firsthand in a fully immersive and safe way.

VR is particularly useful during product and process design or prototype validation, as engineers can visually and interactively review progress through virtual simulations. This approach reduces errors during development and increases overall productivity.

The primary application of VR in Industry is professional training.

Virtual Reality enables employees to train for complex or hazardous tasks before performing them in real-life, eliminating risks and reducing costs for companies.

Due to the level of immersion it offers, VR maximizes knowledge retention, streamlines the learning process, and delivers personalized and self-paced training for each user.

Interested in bringing these technologies to your organization?

If you’d like to learn more about how AR and VR can be applied in industry, we will be happy to help.

INNOVAE AND INDUSTRY 4.0

Digitalization of operations

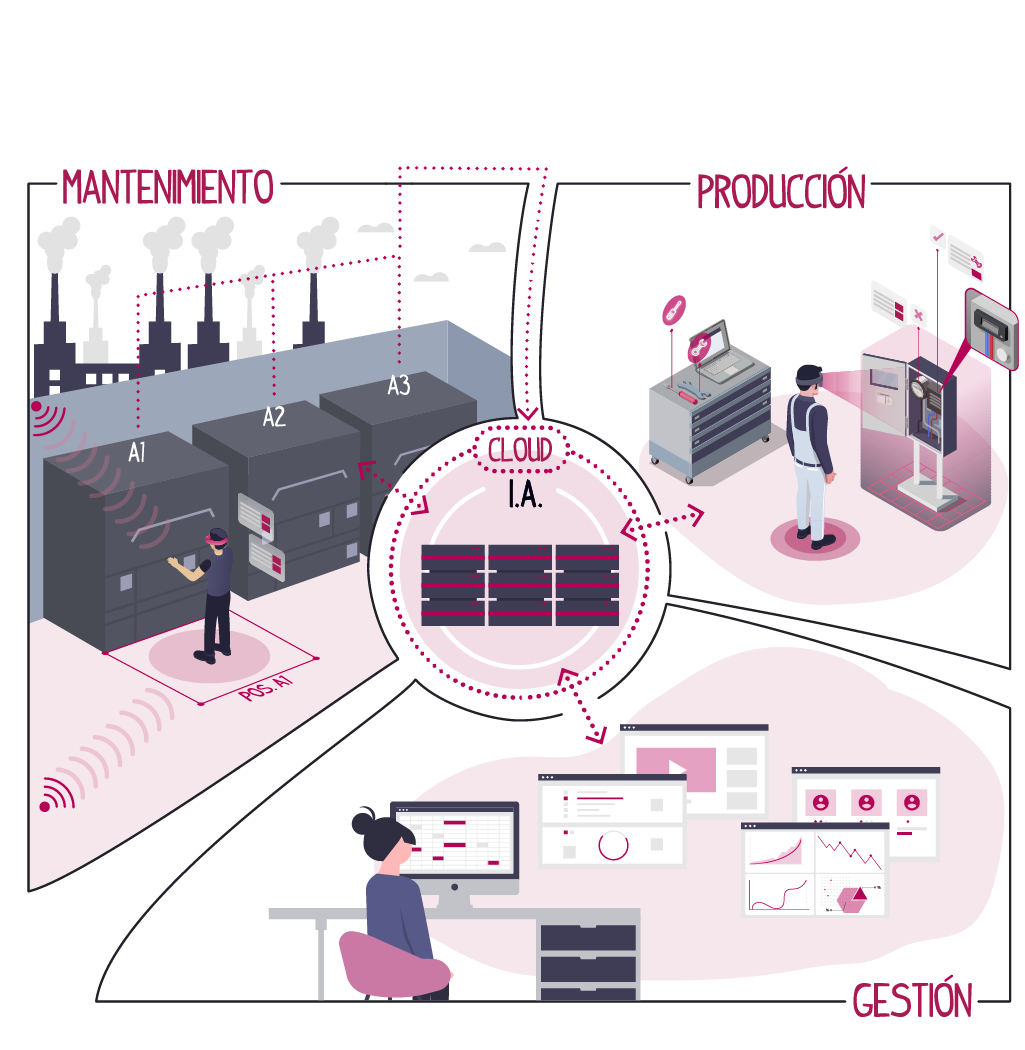

Our solutions for digitizing operations have been designed to empower field technicians, by addressing inefficiencies caused by a lack of critical operational knowledge.

We offer two main products: SAAM, which enables easy digitalization of information and guided process visualization, and ATR, a teleasistance system.

These solutions help improve knowledge management, reduce incident resolution times, and eliminate the need to send experts on site.

They leverage cutting-edge technologies such as augmented reality, cloud computing, and artificial intelligence.

Virtual

Training

Virtual Reality allows employees to practice complex technical procedures or high-risk tasks in realistic virtual settings. The virtual environments replicate real on-the-job scenarios, increasing training efficiency.

We provide a standardized platform, SAVI, which enables comprehensive management of training processes through immersive experiences. Instructors can track user progress, adjust objectives, and select difficulty levels.

We also offer a catalog of standardized training experiences to make adoption of VR training systems seamless for any company.

Digital

Twin

Accessing real-time data from a production facility or machine allows companies to implement advanced data processing and digital twin solutions.

Accessing real-time data from a production facility or machine allows companies to implement advanced data processing and digital twin solutions.

Key applications include monitoring and operating facilities remotely or via Augmented reality, predicting anomalies and optimizing process parameters,and simulating different scenarios without affecting the real environment…

Solutions for assembly and quality control

We provide support systems to assist in assembly and process control tasks within the production facilities.

Using Mixed Reality, our solutions guide operators with step-by-step instructions on the equipment, helping to eliminate errors.

Advanced verification tools reduce quality control times, while real time assistance shortens the training period for new operators.

Interested in learning more about how Innovae can optimize your operations?

Discover how we apply Augmented and Virtual Reality to industry.