Investment in effective ORP (Occupational Risk Prevention) is increasingly necessary, being one of the fundamental pillars that protects the worker from the risks of the working environment. As indicated by the Ministry of Labour and Social Economy, the number of occupational accidents in Spain between January and August 2021 amounts to 730,524. This represents an increase of around 15% over the previous year, showing that awareness-raising is not being sufficiently effective or up to date.

An industrial emergency

The industrial sector, having not only the highest rate of occupational hazards but also a high rate of fatal accidents, faces a huge challenge in ensuring an ORP programme that has the desired effect. With technical processes becoming more and more complex, the traditional methods of ORP no longer respond effectively to the realities of the workplace.

The most frequent problems are a lack of clear and uniform communication of the contents to raise awareness, as well as an inability to properly document the programmes carried out, which does not allow for a precise evaluation of the competences acquired. There is also a lack of impact of the contents, as traditional ORP tools are based on a very passive and unidirectional awareness-raising, in the form of manuals or presentations.

This picture shows the need to adopt new ways of ORP to make the working environment safer, methods that prioritise occupational safety as a matter of urgency in order to combat the trend presented above.

Prevention with Virtual Reality

Virtual Reality, which has been gaining popularity in recent weeks, is one of the big bets for effective job awareness and training.

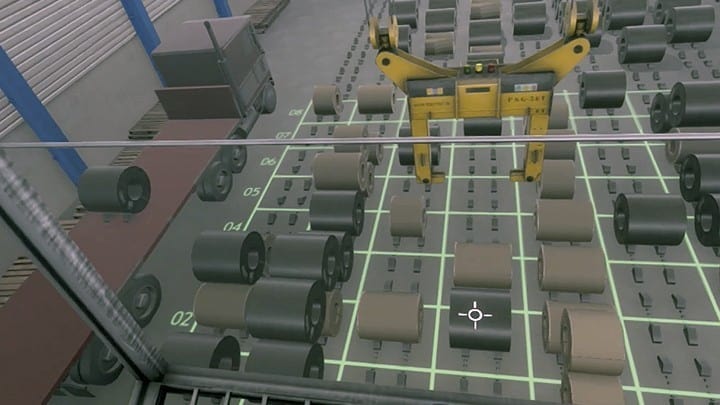

By immersing the user in a 100% computer-generated environment that recreates risk situations in the workplace, technicians can safely explore the reality of occupational hazards.

The savings from training in virtual environments are significant. According to a study by Citrix GoToTraining, companies can save between approximately 8,500€ and 14,000€ by moving from traditional to virtual training. Cost savings are achieved by avoiding travel for both technicians and instructors, as well as reducing lost productivity through the agility with which effective ORP training is achieved.

Example of a virtualised industrial environment

Also, occupational safety departments can have a complete overview of training sessions centrally, without the need for additional tools. Moreover, being able to materialise the factory virtually avoids having to stop machinery for real demonstrations. In essence, the cost minimisation compared to face-to-face training varies between 30% and 70%. Of course, the main benefits extend to the technicians in training.

Thanks to virtual simulations, knowledge retention is optimised, while the learning experience is mentally stimulating and allows learning by doing, triggering user engagement with the content.

The training received, being digitally crystallised, is completely homogenous. This ensures that critical knowledge is not lost in the training of new technicians, reinforcing awareness and thus safety.

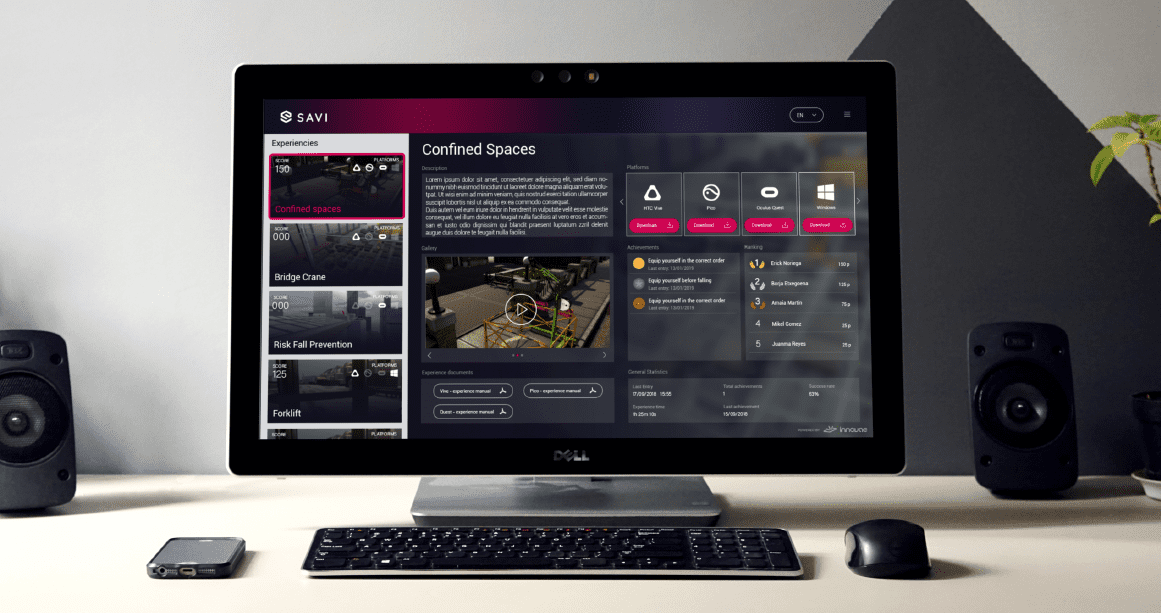

SAVI, our Virtual Learning Solution

At Innovae we offer SAVI, a platform made up of training capsules that allow you to simulate industrial experiences in complete safety.

Whether it is to raise awareness about the handling of industrial machinery, working at heights or the use of cranes, SAVI enables professionals to be trained in the most efficient and convenient way.